Fiber Optic Drone Tripwire

Short Brief

Preston Zen, Natalia Sarapina, Bohdan Hlavatskyi, Viktor Koldun Project Overview This innovative defense system addresses the emerging threat of fiber-optic drones that deploy trailing optical fibers for communication and control. When these fibers contact the ground or obstacles, they can be severed, causing the drone to lose control and operational capability. Our solution involves deploying…

Pledged

0.00 $

Backers

0

Preston Zen, Natalia Sarapina, Bohdan Hlavatskyi, Viktor Koldun

Project Overview

This innovative defense system addresses the emerging threat of fiber-optic drones that deploy trailing optical fibers for communication and control. When these fibers contact the ground or obstacles, they can be severed, causing the drone to lose control and operational capability.

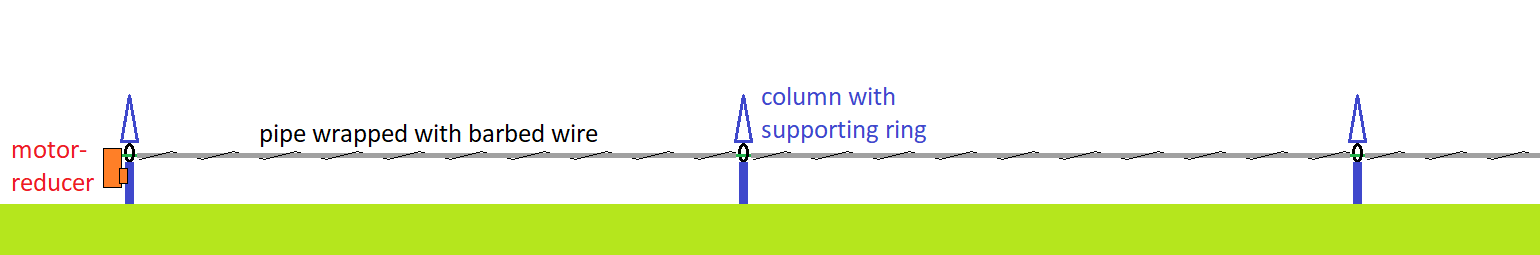

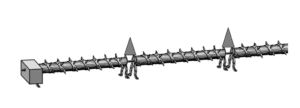

Our solution involves deploying a specialized barrier system around protected areas. This barrier consists of rotating elements designed to immediately capture, bend, and sever any fiber optic cables that come into contact with them. The system utilizes pipes equipped with sharp gripping elements that rotate continuously around their axis, positioned on existing fences or elevated above surrounding vegetation and structures.

Technical Foundation and Patent References

The barrier design draws inspiration from several existing security technologies while incorporating fundamental innovations:

- DE380265C – Solid Wall Fence

- US10/785,964 – Roller Bar Security Device and Fence

- GB2502042A – Barrier with Rotatable Unit Capable of Rotation

- US16/684,448 – Animal Repelling Device

- CA1148397A – Anti-Scale Device, Security Device, and Intruder Barrier

- US17/342,461 – Animal Repelling Device

- GB2234273A – Spiked Rotatable Barrier Element

- US14/185,585 – Configurable Rotary Security Panel Barrier

Key Innovation

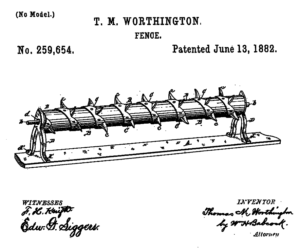

Our design incorporates a critical advancement illustrated in US259654A:

Unlike existing barrier systems that feature independently rotating elements, our design connects all rotating components into a single synchronized rotating assembly driven by a motor reducer system.

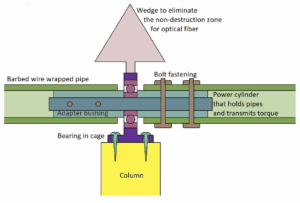

This unified approach ensures that any fiber optic cable contacting the barrier is immediately captured and wound around one of the rotating elements, causing signal disruption and physical separation within just a few rotations. To prevent fibers from becoming lodged at connection points between rotating elements, all joints are equipped with vertical triangular guides.

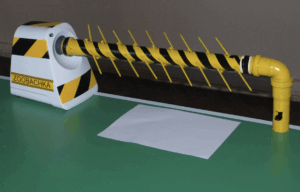

Prototype Testing Results

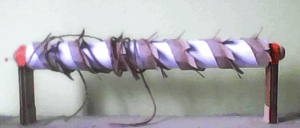

Initial testing on our prototype model demonstrated complete functionality according to design specifications:

However, testing revealed that fiber capture and breakage could require several rotations depending on the angle of contact with the rotating element. Given the time-critical nature of drone defense, we developed an enhanced rotating element design featuring steel pipes with long nails welded at strategic angles.

Experimental validation confirmed that this improved design captures and bends fiber optic cables at any contact angle within a single rotation, immediately disrupting signal transmission. Complete fiber severance occurs within several additional rotations.

Construction Details

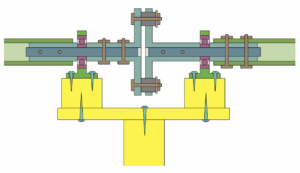

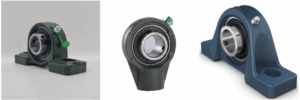

The production system utilizes standard steel water pipes as rotating elements, with long nails welded at optimized angles. Pipe connections feature support bearing assemblies that simultaneously support two rotating elements through adapter sleeves while efficiently transferring torque to subsequent barrier sections:

For installations requiring angular adjustments of rotating elements, dual support bearings are employed with cardan or alternative coupling mechanisms between them:

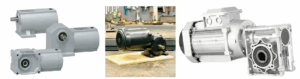

The system is powered by gear motors, with a 1-kilowatt electric motor providing sufficient power for one kilometer of rotating pipe and support infrastructure. Power supply comes from mains electricity with gasoline generator backup systems.

Component Requirements for Full-Scale Implementation

1. Gear Motor (1000± watts, 60± rpm)

2. Motor Control Equipment

3. Three-Phase Electrical Cable

Cable length requirements vary based on barrier location and layout.

4. Thrust Bearings

5. Steel Pipe

- 25mm Welded Steel Pipe

- Metal Products Catalog

- Steel Pipes Selection

- Round Steel Pipes

- Round Steel Pipes Catalog

6. Hardware and Fasteners

Nails, screws, bolts, and general hardware components.

7. Consumables and Services

- Paint, solvents, drill bits, cleaning materials, etc.

- Turner services

- Electric welding services

- Locksmith services

- Transportation and logistics

Cost Analysis

Estimated component and service costs:

- Gear Motor: $450-$900

- Motor Control Equipment: $50-$90

- Electrical Cable: $50-$85

- Thrust Bearings: $50-$100

- Steel Pipe: $100-$130

- Hardware/Fasteners: $30-$50

- Consumables: $50-$65

- Turner Services: $100-$200

- Welding Services: $50-$90

- Locksmith Services: $90-$110

- Transportation: $150-$180

Total Estimated Cost: $1,200 – $2,000

Actual costs may be lower than these estimates. However, given current wartime conditions in Ukraine, precise cost predictions remain challenging.

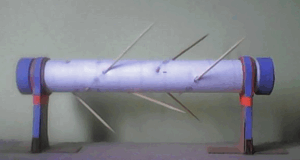

Demonstration Model

A functional demonstration model was constructed to validate system effectiveness. The model successfully met all performance expectations and serves as a fully operational scaled prototype.